October 07, 2024

Alcoa EZCastTM alloy’s third straight NADCA Award for megacasting applications highlights commitment to innovation

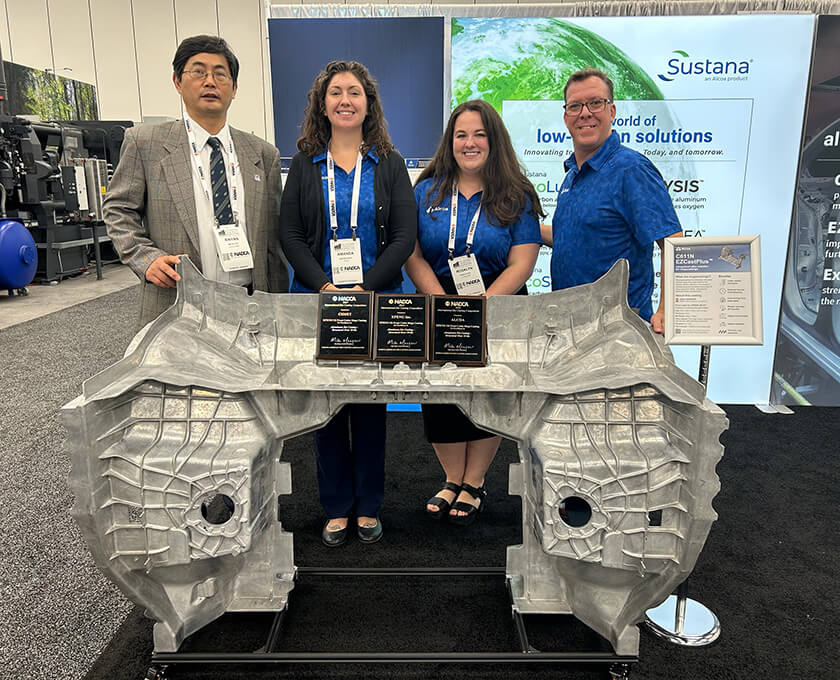

Alcoa took home an award for its innovative EZCastTM alloy family for the third consecutive year at the North American Die Casting Association (NADCA) annual meeting for its application in megacasting.

Alcoa’s commitment to innovation is deeply embedded in its DNA, and this recognition underscores the company’s relentless pursuit of excellence. The EZCastTM alloy family, specifically the EZCastPlus C611N, has set a new benchmark in the automotive industry – particularly in the realm of megacasting.

The award-winning front cabin megacasting for electric SUV is an example of Alcoa’s cutting-edge technology. This single-piece casting replaces more than 50 separate components, significantly simplifying the assembly process and enhancing the vehicle’s structural integrity. The result is a lighter, more robust vehicle that offers superior safety and performance.

For design engineers and original equipment manufacturers (OEM), the benefits of megacasting using EZCastTM alloys are clear:

- Weight Reduction: The front cabin megacasting lightens the vehicle by approximately 33 lbs (15 kg), contributing to improved fuel efficiency and performance.

- Enhanced Safety: The megacasting helps protect occupants and the battery in the event of a crash by directing impact forces away from critical areas.

- Superior Material Properties: The alloy achieves more than 10 percent elongation and over 120 MPa yield strength in its as-cast condition, eliminating the need for dedicated heat treatment and preventing distortion.

- Increased Body Rigidity: The integration of front and rear megacastings with cell-to-body (CIB) battery technology results in body rigidity up to 41,600 N-m, 83 percent greater than traditional designs.

This award is a significant achievement for Alcoa’s dedicated team in Pittsburgh, who have demonstrated exceptional expertise. Winning the NADCA Award for the third year in a row highlights the team’s hard work and the company’s industry leadership.

About the NADCA Award

The NADCA Award recognizes excellence in die casting, with winners selected based on four equally weighted criteria: ingenuity of casting and/or product design, overall quality, cost savings compared with other manufacturing processes, and the part’s contribution to expanding the market for die castings. An independent panel of judges, acknowledged experts with no ties to eligible casters, chooses the winners.