1886

Charles Martin Hall Discovers the Smelting Process

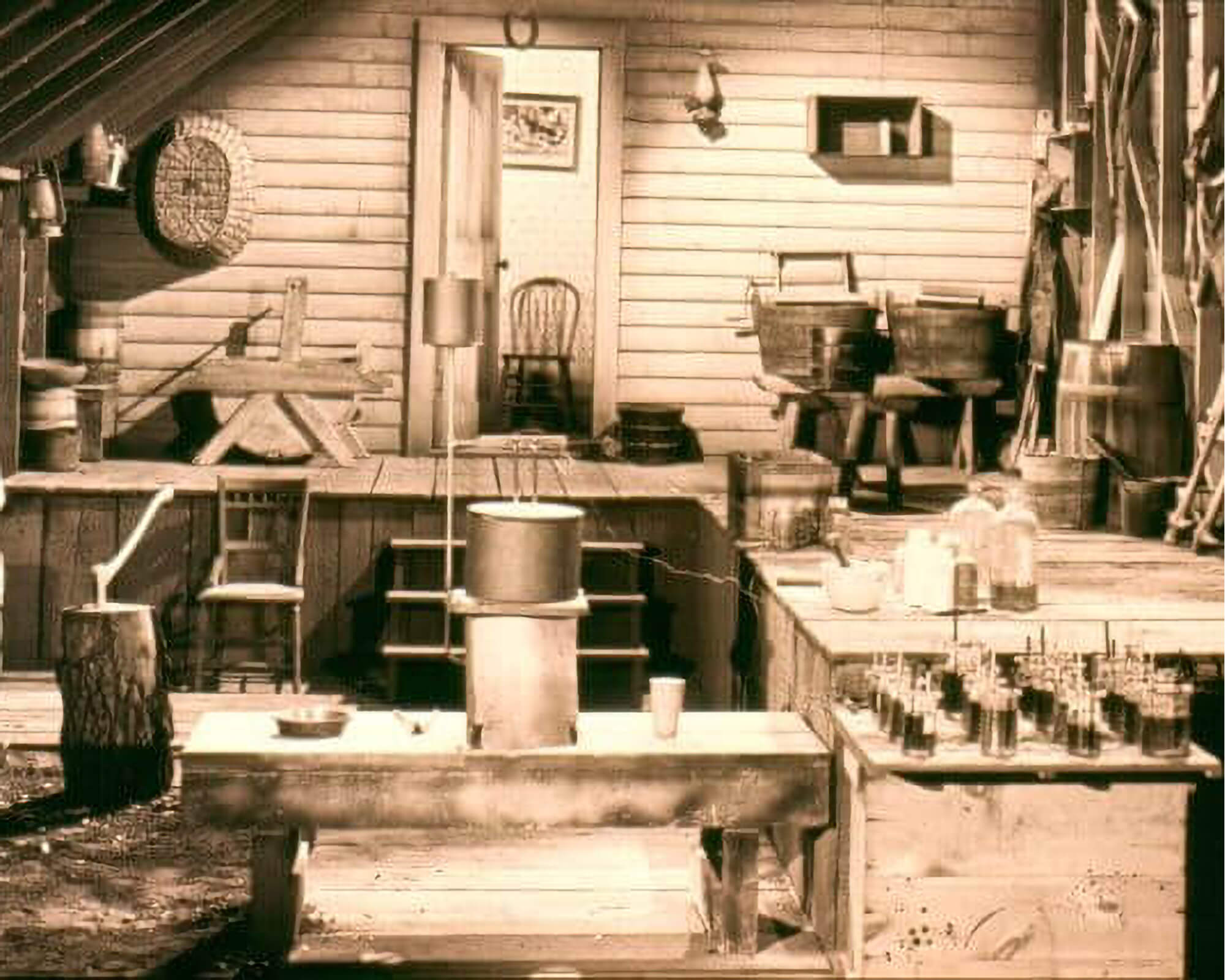

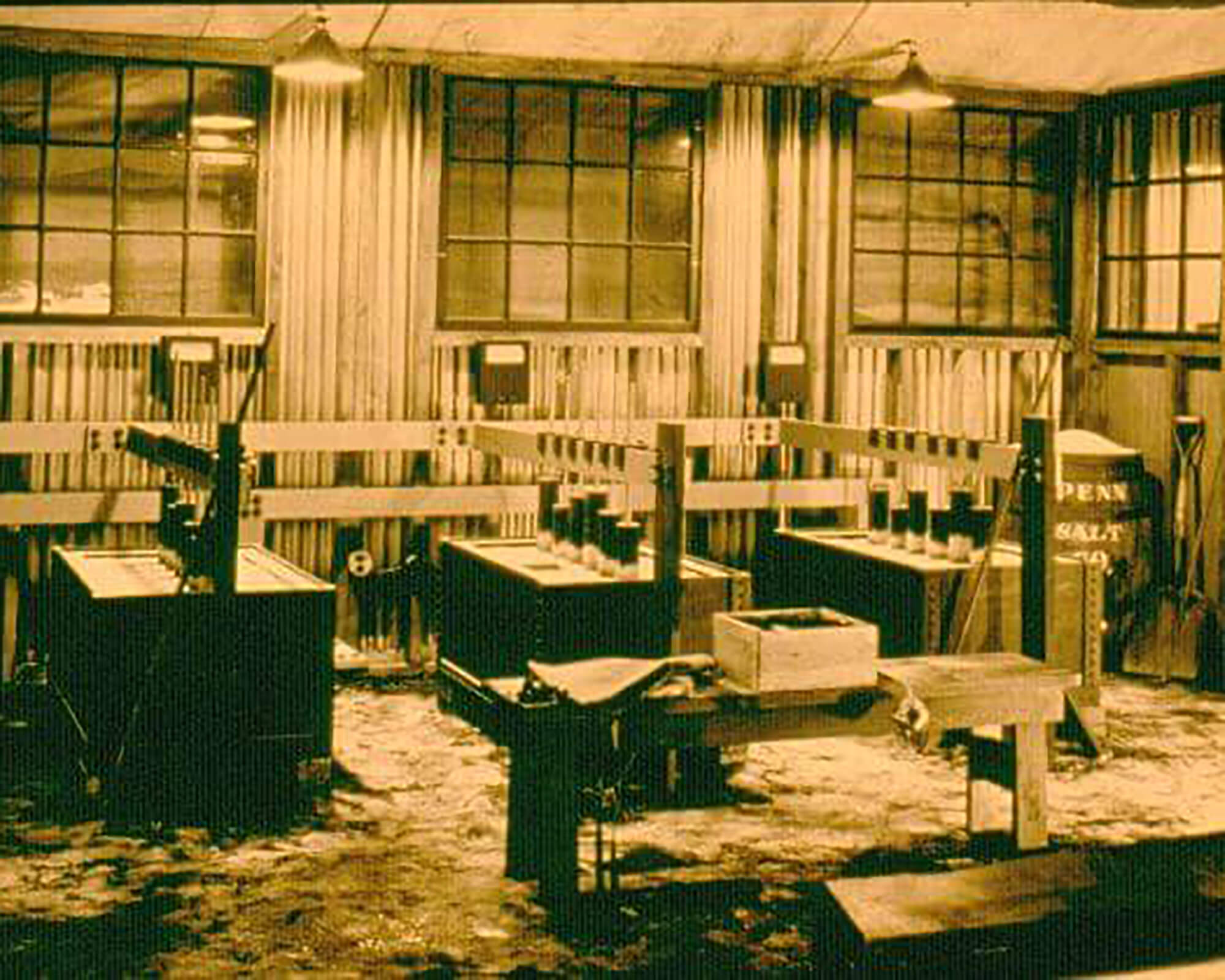

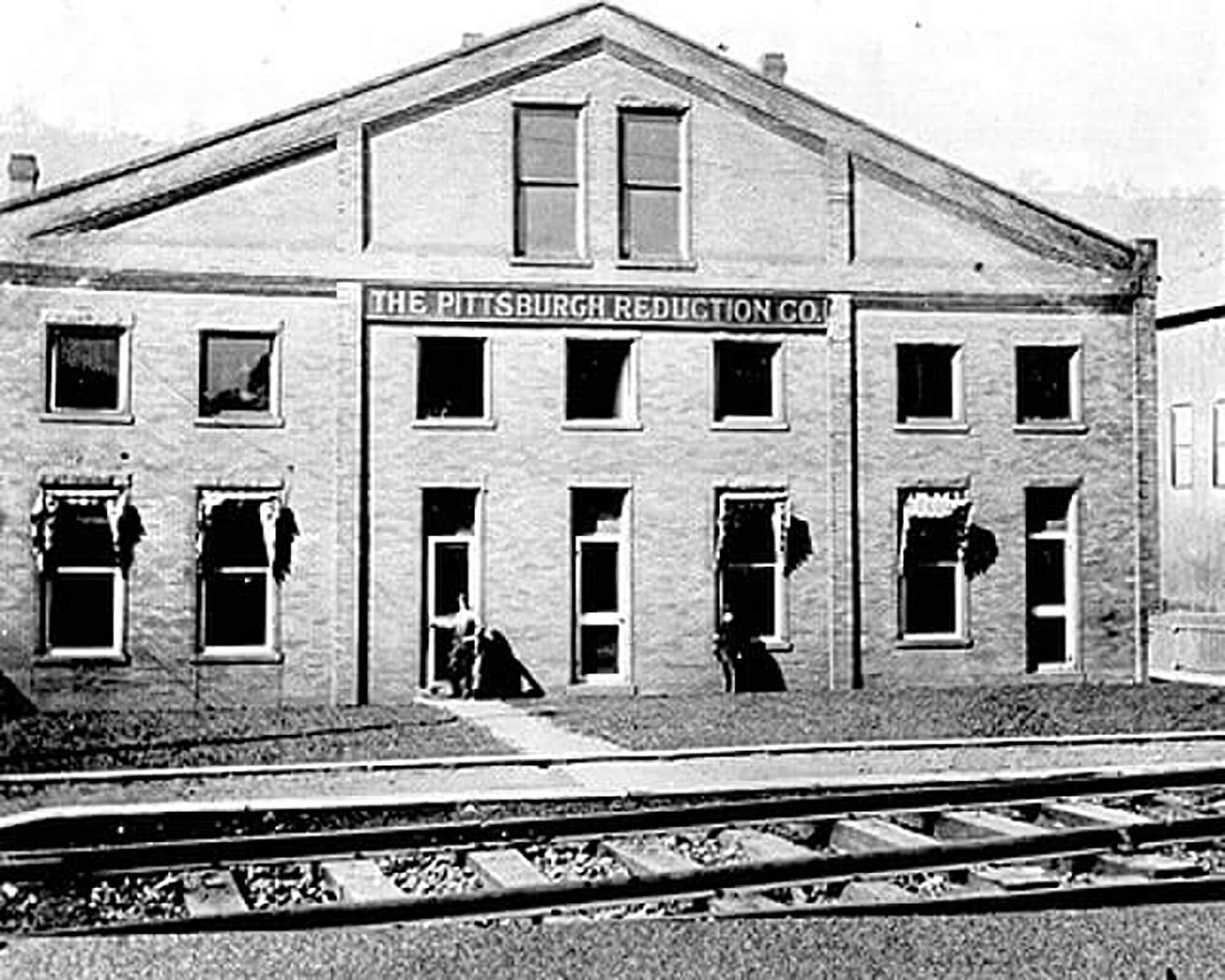

Working with his sister Julia in a shed attached to the family home in Oberlin, Ohio, chemistry student Charles Martin Hall discovers a way to produce aluminum through electrolysis that drastically reduces its cost. Around the same time, the same process is discovered by chemist Paul T. Héroult of France, and it comes to be known as the Hall-Héroult Process. Today, the Hall-Héroult Process is the one method by which every aluminum producer in the world operates.