Innovative Products

Innovating towards zero carbon

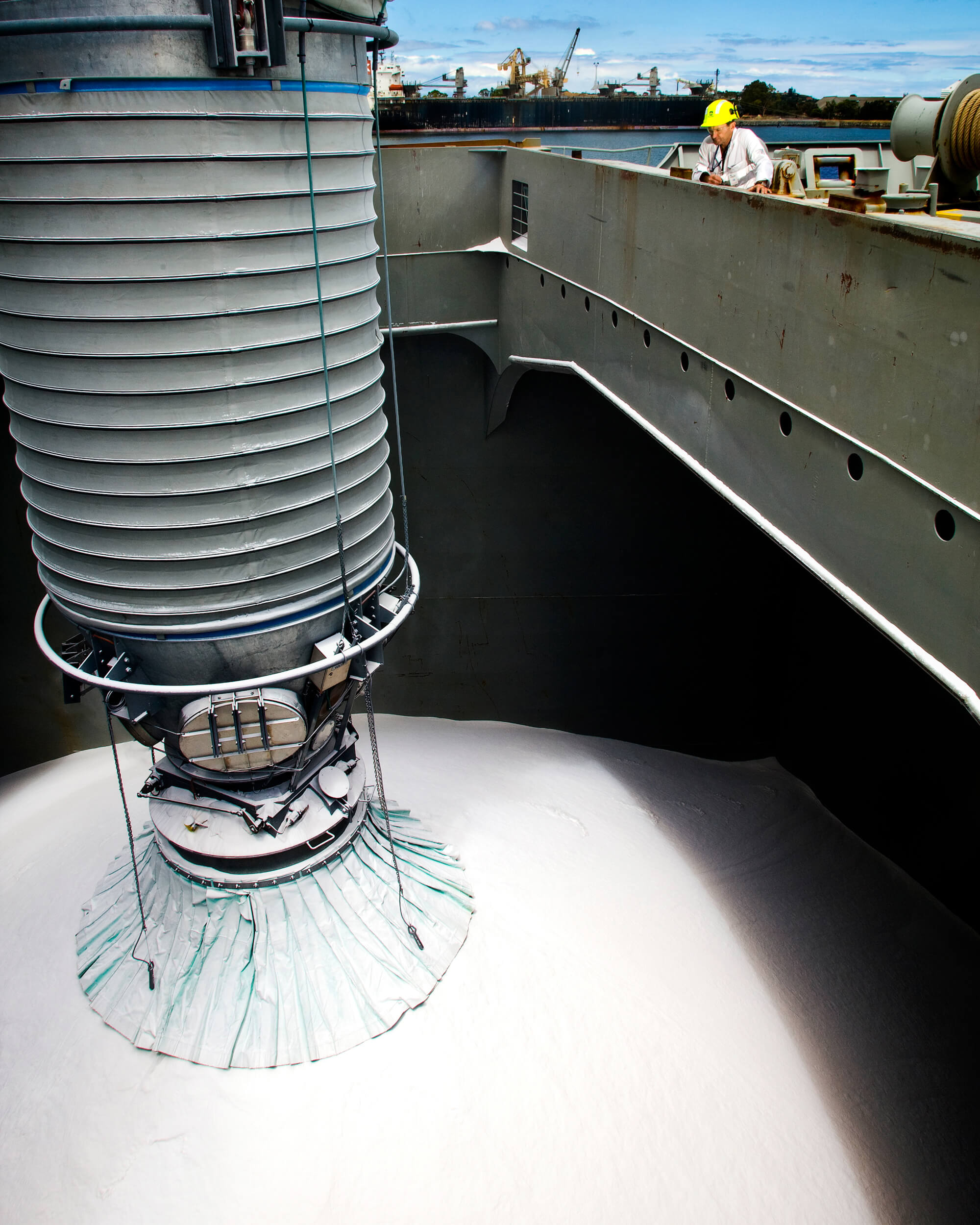

As pioneers in the production of aluminum, we have introduced innovation after innovation throughout the entire value chain, bringing improved efficiency and sustainable practices from mining to refining to smelting.